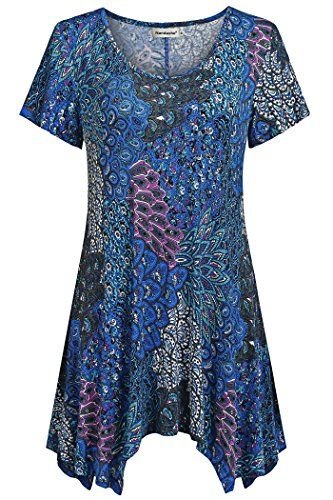

It means the textile formed in the way of weaving (Perpendicular Thread Alignment), and often formed on a loom. Compared to the knit pieces, these are stiffer and sometimes we call it cotton fabrics. Almost all the garments factories we are associated with, are the producers of woven garments. Some common types of woven garments that we're now ready to supply, includes-

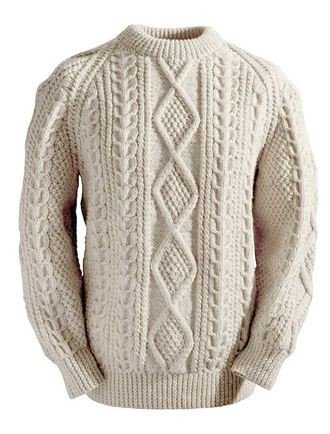

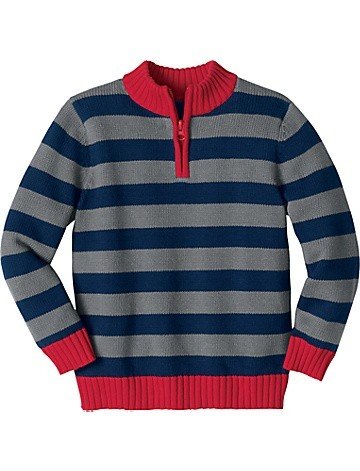

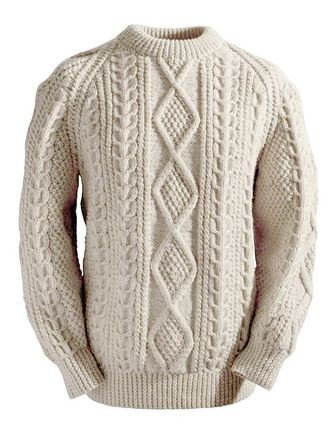

In comparison with weaved fabrics, the knitted fabric is thick and here threads (Bights) running is parallel. And the pieces made from knitted fabrics become more stretchable and elastic. Knitting wear is for you if you want to get Moisture Absorbing one or Wrinkle Resistant Pieces. This type of wear is also easy chic and comfortable so people commonly choose this type for home wearing. Currently our associated knitwear factories are producing following types of wears-

It's commonly a long sleeve knitted garment, and produces for our upper body parts. Now our listed sweater factories are many in number so we're able to provide different types of sweaters. Even you'll get from us more complex sweaters, from 3 to 12 gauge. Some common sweater that almost all our listed sweater factories produces, are-

A good number of our listed garments factories are now giving importance on producing dresses with fashionable handicrafts. Simply it's the making of different decorative objects on the cloth for improving its beauty level. The decorative object may be domestic or otherwise, but the specialty is, workers make it with their own hand, without using a machine. Some common forms of handicrafts are- Applique (Ornamental needlework to form a complete charming image of something) Crocheting (Making textile through crochet using) Embroidery (More intricate than Applique) Felt-making (Combining & Compressing to produce felt) Lace-making (Producing handmade lace- cord or string, on a piece) Macrame (Using cords or knotting threads, making fringe or coarse lace) Quilting (Process of joining at least three layers of fabric) Tapestry art (Fascinating weft-faced weaving where warp threads will be unseen)

You know the interface between the Buyer & Exporter is Merchandiser, so we have an efficient team for Merchandising. This team has a team leader with 15 years experience in this field and 5 other Senior Merchandisers with at least 10 years experience. All of them are functional Merchandisers, and this team also has other necessary supporting staff. The responsibility of this team is to analyze and execute the order according to the costing and pricing. Strictly maintaining the time and action calendar, this team discharges their onerous responsibility. With checking all the orders, preparing documentation, and doing other necessary jobs, this team is like a bridge between buyers and us.

This team is for providing the best sampling to our clients and also for providing design solutions to them. We arrange frequent training sessions for this team as they have to introduce newer ideas more often. At least one member from this team stays online to immediately serve our valuable customers. A good number of designers are now in this team and they're able to find out the best design solution for you in a very short time. All the members of this team are responsible for reporting to the Research & Development/Design team leader about everyday activities. These designers are very much aware of different manufacturers' developed innovative thoughts, and how to improve those.

After getting an order from buyers, we check all the details like desired design, sketch, yarn composition, etc. The job of the Production & Technical Department is to do that and to provide samples accordingly. A good number of decade long experienced merchandisers and quality controllers are in this department. Generally we provide samples to the buyers for their approval, and we step forward accordingly. If the buyer sets some additional criteria, then this department will try hard to meet the criteria. If the order quantity is very large, then we take some additional measures, like time to time reporting, giving more samples, and the like. Mainly this department works in three phases- Pre-production, Production, and During Shipment. 1. In the pre-production level Production & Technical department analyze the order thoroughly again and again. And then, give direction to the factories to provide a sample meeting the buyer's criteria. If the buyer approves the sample, with or without minor correction, then we step forward towards the production level. 2. After obtaining the approval from the buyer, we provide the specification of the order to the factory and thus production level starts. That specification includes order quantity, delivery time, determined quality, buyer's guideline (if any), etc. If the production time is longer, then this department visits the factory several times to ensure that everything goes okay. 3. Work of this department during shipment includes receiving the ordered pieces, and checking primarily. After such primary checking, this team handovers items to the merchandising team after completing some pre-works for ensuring quality. We give much importance to in-time shipment, so we try to collect the ordered pieces while a few days are still left.

All the members of this department have many years of production background. So they can detect the good and bad of a produced item in just minutes. The responsibility of this department is the inspection of- Fabrics, Incoming Materials, Packaging & Loading, and something like that. Random Inspection of them is very effective to provide superb quality shipment. We do Final Random Inspection (FRI) during packing the goods before delivering to our clients. Through such regular inspection, we ensure and enhance transparency. And due to such transparency there’s no risk at all of rejecting a shipment. Factory Inspection We're not on behalf of accepting order and making benefits, human rights issues really matter to us. That's why we randomly visit our associated factories to ensure the better working environment for workers. And sometimes, on a full time basis, our team stations in the factory in the time of producing ordered pieces. On identifying any risk factor, we immediately report to the factory management, and do the other needful. According to our policy, we're bound to conduct Inline Inspection regularly at Acceptable Quality Level 2.5. And we send the report of such inspections to parties concerned, like- factory high-ups, our top management, and some others.

Chairman

Managing Director

Co-Chairman

CEO